Obviously waste heat recovery comes along with a capital Expense. Assignments must be assessed on someone foundation, taking into account recent gas expenditures, managing hours, long run manufacturing facility requirements, issue of existing gear and the like.

They develop waste heat which can be recycled. Engines and Turbines : Energy technology units, which include engines and turbines, generate waste heat in the course of their combustion course of action. Industrial processes: like steelmaking and glass manufacturing build waste heat for a byproduct. Chemical reactions also deliver heat through production. Several industries broadly use steam in steam systems for functions like heating, sterilization, and power era. The condensate and minimal-tension steam from these systems may be sources of waste heat. Industrial products: like machinery, motors, and transformers can generate waste heat through Procedure in industrial processes. You may Get well and repurpose this heat. Heat exchangers: Industries commonly use thermal exchangers to transfer heat from a person medium to another in various industrial procedures. If they don't optimize the heat transfer, they can deliver waste heat. Waste heat is difficult in order to avoid, but we can utilize it in new methods to make Strength practices more sustainable. Learn more about waste heat systems. As we proceed to create cleaner technologies, Permit’s also take into consideration how we will take advantage of of every joule of Electricity, even the seemingly “wasted” kinds. Go on studying concerning the takes advantage of of waste heat Related Articles or blog posts

Gasoline turbines (GT) are considered among the list of cleanest technologies to create heating and energy, considering the fact that their emissions of NOx and CO2 are much reduced than other industrial combustion-form key movers. The gas turbine is thought to operate based on the Brayton cycle. Inside the Brayton cycle, atmospheric air is compressed, heated, and mixed with fuel in the combustor. The blended air and gas are then burned. The expanded fuel is then employed to operate the turbine to crank out electric power.

In TVR, motive steam at comparatively increased tension is utilized to compress the LP flash steam employing a steam ejector, and after that delivered at an intermediate stress.

It is also vital that you keep an eye on and Examine the overall performance and impacts of waste heat recovery systems also to share greatest tactics and lessons figured out. By doing so, waste heat recovery can Engage in a key part in acquiring net zero and decarbonisation ambitions for industrial producing.

Concurrently, most corporations consume a lot of Electricity and money to generate incredibly hot method drinking water, space heating or preheat h2o for steam generation.

Enhancing here Electrical power conservation and performance is essential in acquiring carbon neutrality and restricting world warming. Liquid metals with minimal melting factors are swiftly rising as Highly developed materials for economical heat recovery. Owing to some great benefits of liquid metals, for example their minimal melting stage, superior boiling position, large thermal/electrical conductivity, nonflammability, and nontoxicity, liquid-metallic convection could be placed on create significant-temperature waste heat recovery systems that may accommodate heat flux at temperatures earlier mentioned 600 °C, with a convective heat transfer coefficient exceeding 10,000 W/(m2·K). Also, liquid-metal thermoelectric and magnetohydrodynamic generators can Get well very low-quality and reduced-temperature heat to make energy. Liquid-metal-dependent heat recovery systems have progressed drastically in academia, and normal programs dependant on these technologies are actually applied inside the metal and chemical industries.

Waste heat recovery can contribute substantially to net zero and decarbonisation plans for industrial producing, by decreasing the Strength use and emissions from heating and cooling systems. In accordance with the Intercontinental Strength Agency (IEA), waste heat recovery could Lower global CO2 emissions from industrial production by 1.

, statements to recover waste heat in excess of a wide temperature selection with much better effectiveness. Biasi [ 9] reviewed the appliance of CCLC to enhance gasoline turbine ability and effectiveness.

Instead of merely eliminating the heat through the airend, it may be used to crank out no cost hot system h2o or nutritional industrial waste heat recovery supplement hot h2o heating systems by utilising a superior-performance oil-water heat exchanger – factory fitted, retro fitted or to be a CompAir energy recovery box.

Ordinarily, waste heat at large temperatures is usually utilized with an increased performance and with much better economics. Also, additional engineering solutions can be found for converting waste heat at superior temperatures into other practical Vitality varieties than waste heat at reduced temperatures

This unused “waste heat” is provided off to your surrounding setting in the shape of exhausts or effluents at various temperature amounts. Recovering this waste heat can enormously decrease the usage of Main fuels and, thus, emissions.

The recovery and reuse of waste heat presents a significant possibility for almost any country to cut back its Total Most important Vitality utilization. Reuse of waste heat enhances the ambient air quality by lowering both equally industrial air pollution and greenhouse fuel emissions from industries. This paper presents an estimation of thermal waste heat possible in five Strength-intense industrial sectors (i.e., iron and metal, chemical and petrochemical, paper and pulp, cement, and glass), based upon details accessible inside the extant literature and federal government stories.

An enclosed, air cooled compressor with defined air outlet can transfer the total degree of heat with the cooling air for ambient air heating:

Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Michael J. Fox Then & Now!

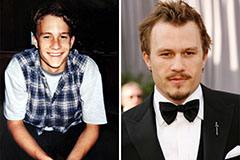

Michael J. Fox Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!